-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

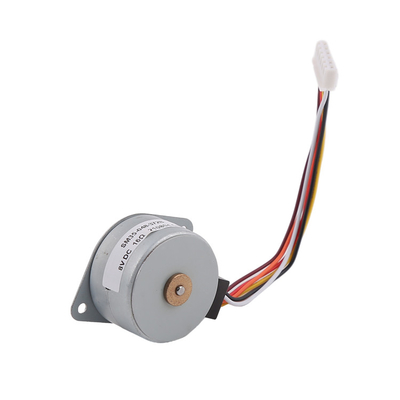

High Torque 35mm Micro Stepper Motor For 3D Printer 35mm Motor Size 4 Phases

| Place of Origin | China |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS |

| Model Number | SM35-048 |

| Minimum Order Quantity | 1Unit |

| Price | $2~5/unit |

| Packaging Details | The product is packed with pearl cotton, and the outside is in a carton. |

| Delivery Time | 10~30 days after receiving sample payment |

| Payment Terms | MoneyGram, Western Union,Credit Card,T/T, L/C |

| Supply Ability | 100000\ Units/year |

| Model No. | SM35-048 | Motor Type | Micro Stepper Motor |

|---|---|---|---|

| Step Angle | 7.5±7% | Motor Size | 35mm |

| No. Of Phases | 4 Phases | Current Per Phase | 0.5A |

| Minimum Order Quantity | 1unit | ||

| Highlight | 35mm Micro Stepper Motor,3D Printer Micro Stepper Motor,4 Phases 35mm Stepper Motor |

||

High Torque Micro 35mm Stepper Motor For 3D Printer 35mm Motor Size 4 Phases

Description

There are two winding methods for stepper motors: bipolar and unipolar.

1.Bipolar Motors

Our bipolar motors generally have only two phases, phase A and phase B, and each phase has two outgoing wires, which are separate winding. There is no connection between the two phases. Bipolar motors have 4 outgoing wires.

2.Unipolar motors

Our unipolar motors generally have four phases. On the basis of two phases of bipolar motors, two common lines are added.

If common wires are connected together, the outgoing wires are 5 wires.

If common wires are not connected together, the outgoing wires are 6 wires.

An unipolar motor has 5 or 6 outgoing lines.

Parameters

| Voltage | 8DV DC |

| No.of Phase | 4 Phase |

| Step Angle | 7.5°±7% |

| Winding Resistance(25℃) | 16Ω±10% |

| Current phase | 0.5A |

| Detent torque | ≤110g.cm |

| Max Pull-in Rate | 400PPS |

| Holding Torque | 450g.cm |

| Winding temperature | ≤85K |

| Didlectric Strength | 600 VAC 1SEC 1mA |

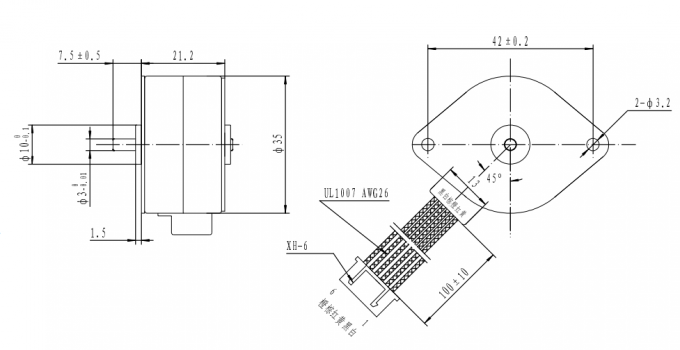

Design Drawing

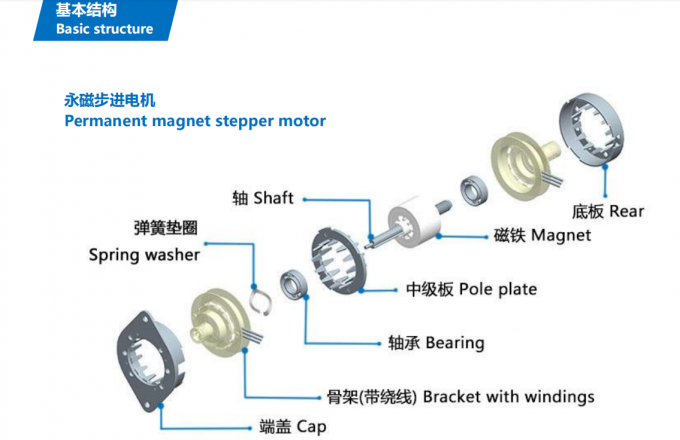

About the basic structure of PM stepper motor

Features & Advantage

1. High precision positioning

Since steppers move in precise repeatable steps, they excel in applications requiring precise

positioning, by the number of steps the motor moves

2. High Precision speed control

Precise increments of movement also allow for excellent control of rotational speed for process

automation and robotics. The rotational speed is determined by the frequency of the pulses.

3. Pause and holding function

With control of the drive, the motor has lock function (there is current through motor windings, but

the motor does not rotate), and there is still a holding torque output.

4. Long life & low electromagnetic interference

The stepper motor has no brushes, and does not need to be commutated by brushes like a brushed

DC motor. There is no friction of the brushes, which increases the service life, has no electric sparks, and reduces electromagnetic interference.

Application of PM stepper motor

Printer

Textile machinery

Industrial control

Air conditioning

Working principle of stepper motor

The drive of the stepper motor is controlled by software. When the motor needs to rotate, drive will

apply the stepper motor pulses. These pulses energize stepper motor's in a specified order, thereby

causing the motor's rotor to rotate in a specified direction (clockwise or counter clockwise). So as to

realize proper rotation of the motor. Each time the motor receives a pulse from the driver, it will rotate by a step angle (with full-step drive), and the rotation angle of the motor is determined by the number of driven pulses and step angle.

Lead time and packaging information

Lead time for samples:

Standard motors in stock: within 3 days

Standard motors not in stock: within 15 days

Customized products: About 25~30 days (based on complexity of customization)

Lead time for building a new mold: generally about 45 days

Lead time for mass production: based on order quantity

Packaging:

Samples are packed in foam sponge with a paper box, shipped by express

Mass production, motors are packed in corrugated cartons with transparent film outside. (shipping by air)

If shipped by sea, product will be packed on pallets

Payment method and payment terms

For samples, in general we accept Paypal or alibaba.

For mass production, we accept T/T payment.

For samples, we collect full payment before production.

For mass production, we can accept 50% pre-payment before production, and collect the rest 50% payment before shipment.

After we cooperate order more than 6 times, we could negotiate other payment terms such as A/S (after sight)