-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

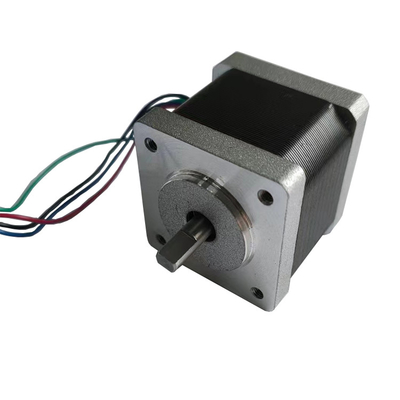

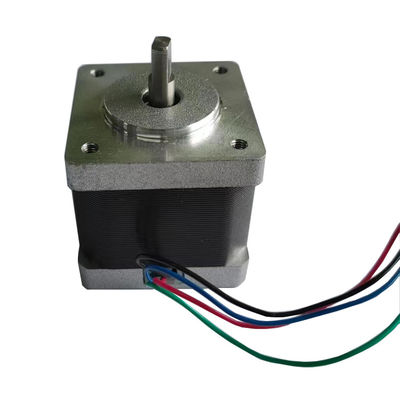

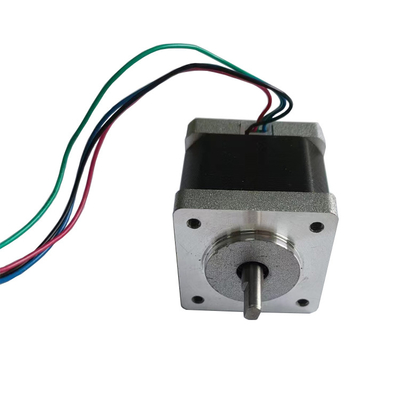

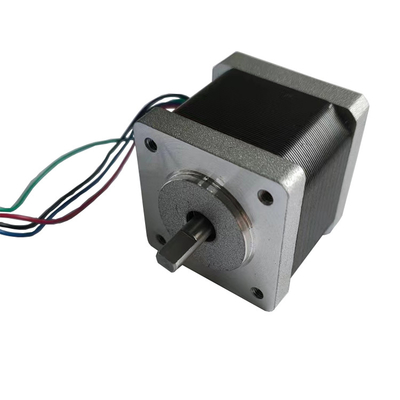

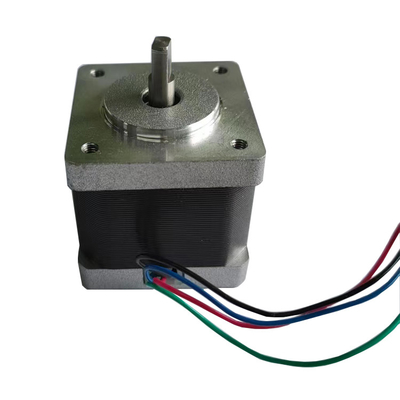

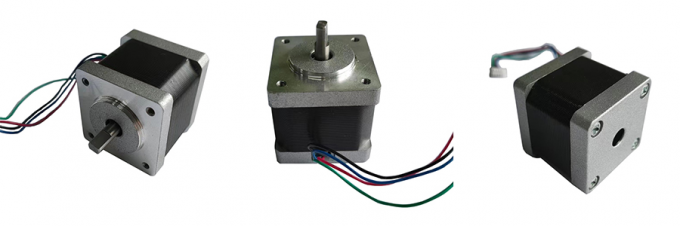

Planetary Gearbox Stepper Motor 35mm (NEMA 14) Square Hybrid Stepper Motor

| Place of Origin | China |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS |

| Model Number | 35HS |

| Minimum Order Quantity | 1Unit |

| Price | $8-15/Unit |

| Packaging Details | The product is packed with pearl cotton, and the outside is in a carton. |

| Delivery Time | 10~30 days after receiving sample payment |

| Payment Terms | MoneyGram, Western Union,Credit Card,T/T, L/C |

| Supply Ability | 100000\ Units/year |

| Motor Type | Hybrid Stepper Motor | Step Angle | 0.9°or 1.8° |

|---|---|---|---|

| Motor Size | 35mm(NEMA 14) | No. Of Phases | 2 Phases (bipolar) |

| Rated Current | 0.5~1A/phase | Motor Length | 27~42mm |

| Minimum Order Quantity | 1unit | ||

| Highlight | 35mm Square Hybrid Stepper Motor,NEMA14 Hybrid Stepper Motor,Square Planetary Gearbox Stepper Motor |

||

Description

This is a planetary gearbox stepper motor 35mm (NEMA 14) square hybrid stepper motor.

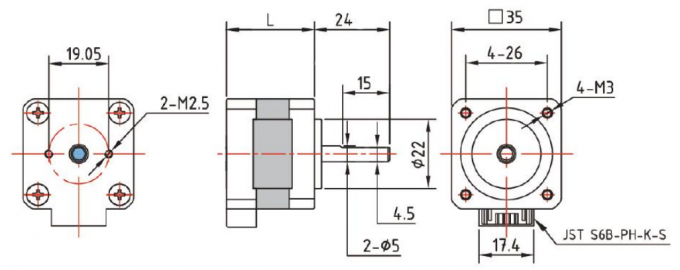

The motor length for this product is generally between 27 and 42mm, special lengths can be customised. The longer the length, the higher the torque of the motor.

Hybrid stepper motors are generally square in shape and stepper motors can be identified by their distinctive external shape.

In addition, there are two options for the stepping angle of the motor: 0.9 degrees and 1.8 degrees.

The type of output shaft, our standard shaft is a D-shaft, this can be customised to suit the user's requirements.

The length of the lead wire and the type of connector can also be used with standard connectors, which can also be customised.

A hybrid stepper motor is available with a 1.8° step angle (200 steps/revolution) or 0.9° step angle (400 steps/revolution). or 0.9° step angle (400 steps/revolution). The stepping angle is determined by the number of teeth on the rotor blades.

It can also be fitted with a gearbox, which has different gear stages for different speed ratios and of course different lengths, the longer the length the lower the efficiency.

Parameters

|

Step Angle (°) |

Motor length (mm) |

Holding torque (g*cm) |

Current /phase (A/phase) |

Resistance (Ω/phase) |

Inductance (mH/phase) |

No. of leads |

Rotational inertia (g*cm2) |

Weight (KG) |

| 0.9 | 27 | 1000 | 0.5 | 10 | 14 | 4 | 6 | 0.13 |

| 1.8 | 28 | 1000 | 0.5 | 20 | 14 | 4 | 11 | 0.13 |

| 0.9 | 34 | 1200 | 1 | 2 | 3 | 4 | 9 | 0.17 |

| 1.8 | 34 | 1400 | 1 | 2.7 | 4.3 | 4 | 13 | 0.17 |

| 0.9 | 40 | 1500 | 1 | 2 | 4 | 4 | 12 | 0.22 |

| 1.8 | 42 | 2000 | 1 | 3.8 | 3.5 | 4 | 23 | 0.22 |

Above parameters are standard products for reference, motor can be customized based on customer's requirement.

Design Drawing

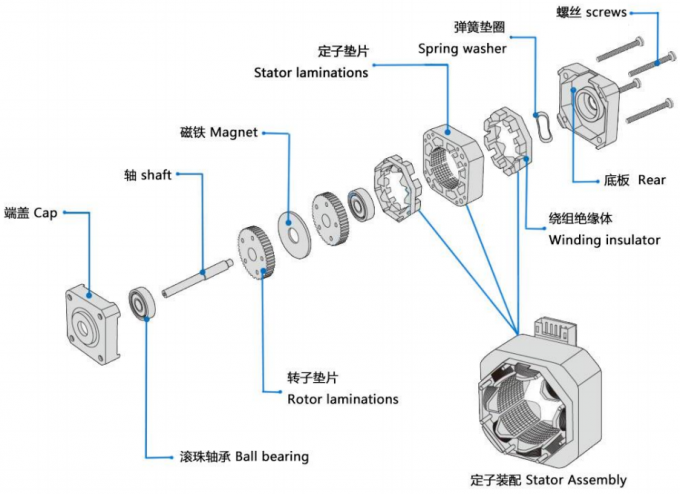

Basic structure of NEMA stepper motors

Application of Hybrid stepper motor

Due to high resolution of hybrid stepper motor’s (200 or 400 steps per revolution), they are widely used for applications requiring high precision, such as:

3D printing

Industrial control(CNC, automatic milling machine, textile machinery)

Computer peripherals

Packing machine

And other automatic systems requiring high precision control.

Notes about hybrid stepper motors

Customers should follow the principle of “selecting stepper motors first, then select driver based on existing stepper motor”

It is best not to use the full-step driving mode to drive a hybrid stepping motor, and the vibration is bigger under full-step driving.

Hybrid stepper motor is more suitable for low-speed occasions. We suggest the speed does not exceed 1000 rpm (6666PPS at 0.9 degrees), preferably between 1000-3000PPS (0.9 degrees), and it can be attached with a gearbox to lower it’s speed. The motor has high working efficiency and low noise at suitable frequency.

Due to historical reasons, only the motor with a nominal 12V voltage uses 12V. Other rated voltage on design drawing is not exactly the most suitable driving voltage for the motor. Customers should choose suitable driving voltage and suitable driver based on own requirement.

When the motor is used with high speed or large load, it generally does not start at the working speed directly. We suggest to gradually increases the frequency and speed. For two reasons: First, the motor does not lose steps, and second, it can reduce noise and improve the positioning accuracy.

The motor should not work in the vibration area(below 600 PPS ). If it must be used at slow speed, vibration problem could be reduced by changing the voltage, current or adding some damping.

When the motor works below 600PPS (0.9 degrees), it should be driven by small current, large inductance and low voltage.

For loads with a large moment of inertia, a large size motor should be selected.

When higher precision is required, it could be solved by adding gearbox, increasing the motor speed, or using subdivision driving. Also a 5-phase motor(unipolar motor) could be used, but the price of the entire system is relatively expensive, so it’s rarely used.

Stepper motor size:

We currently have 20mm(NEMA8), 28mm(NEMA11), 35mm(NEMA14), 42mm(NEMA17), 57mm(NEMA23), 86mm(NEMA34) hybrid stepper motors. We suggest to determine motor size first, then confirm other parameter, when you select a hybrid stepper motor.

定制服务:

Customization service:

We provide customization service on motor including lead wire number(4wires/6wires/8wires), coil resistance, cable length and color, also we have multiple height for customers to choose.

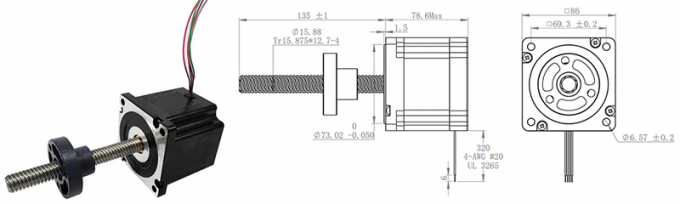

Regular output shaft is D shaft, if customers require leads screw shaft, we provide customization service on lead screws, and you can adjust lead screw type and shaft length.

Picture below is a typical hybrid stepper motor with trapezoidal lead screw.

Lead Time

If we have samples in stock, we can ship out samples in 3 days.

If we do not have samples in stock, we need to produce them, production time is about 20 calendar days.

For mass production, lead time depends on order quantity.

Payment method and payment terms

Payment method and payment terms:

For samples, in general we accept Paypal or alibaba.

For mass production, we accept T/T payment.

For samples, we collect full payment before production.

For mass production, we can accept 50% pre-payment before production, and collect the rest 50% payment before shipment.

After we cooperate order more than 6 times, we could negotiate other payment terms such as A/S (after sight)

FAQ

1.How long is the general delivery time for samples? How long is the delivery time for back-end large orders?

Sample order lead-time is about 15 days,mass quantity order lead -time is 25-30 days.

2.Do you accept custom services?

We accept products customize.including the motor parameter,lead wire type,out shaft etc.

3.Is it possible to add an encoder to this motor?

For this type motor, we can adding encoder on the motor wear cap.