-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

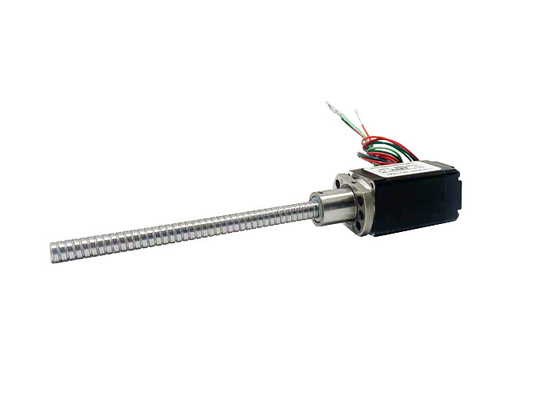

Nema 8 (20mm) hybrid ball screw stepper motor 1.8° Step Angle Voltage 2.5 / 6.3V Current 0.5A,4 Lead Wires

| Place of Origin | China |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS |

| Model Number | VSM20BSHSM |

| Minimum Order Quantity | 1Unit |

| Price | $86~$214/Unit |

| Packaging Details | Standard export package, or can be customized |

| Delivery Time | 15-30 work days |

| Payment Terms | Western Union, T/T, L/C, MoneyGram |

| Supply Ability | 1000000 Units/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Motor Size | 20mm | Step Angle | 1.8° |

|---|---|---|---|

| Voltage (V) | 2.5 / 6.3 | Current (A) | 0.5 |

| Resistance (Ohms) | 5.1 / 12.5 | Inductance (mH) | 1.5 / 4.5 |

| Lead Wires | 4 | City | Changzhou |

| Highlight | 1.8° hybrid ball screw stepper motor |

||

Nema 8 (20mm) hybrid ball screw stepper motor 1.8° Step Angle Voltage 2.5 / 6.3V Current 0.5A,4 Lead Wires

Nema 8 (20mm) hybrid stepper motor, bipolar, 4-lead, ball screw, low noise, long life, high performance, CE and RoHS certified.

![]()

Descriptions:

|

Product Name |

20mm hybrid ball screw stepper motor |

|

Model |

VSM20BSHSM |

|

Type |

hybrid stepper motors |

|

Step Angle |

1.8° |

|

Voltage (V) |

2.5 / 6.3 |

|

Current (A) |

0.5 |

|

Resistance (Ohms) |

5.1 / 12.5 |

|

Inductance (mH) |

1.5 / 4.5 |

| Lead Wires | 4 |

|

Motor Length (mm) |

30 / 42 |

| Ambient Temperature | -20℃ ~ +50℃ |

| Temperature Rise | 80K Max. |

| Dielectric Strength | 1mA Max. @ 500V, 1KHz, 1Sec. |

| Insulation Resistance | 100MΩ Min. @500Vdc |

Certifications:

![]()

Electrical Parameters:

| Motor Size |

Voltage/ Phase (V) |

Current/ Phase (A) |

Resistance/ Phase (Ω) |

Inductance/ Phase (mH) |

Number of Lead Wires |

Rotor Inertia (g.cm2) |

Motor Weight (g) |

Motor Length L (mm) |

| 20 | 2.5 | 0.5 | 5.1 | 1.5 | 4 | 2 | 50 | 30 |

| 20 | 6.3 | 0.5 | 12.5 | 4.5 | 4 | 3 | 80 | 42 |

VSM20BSHSM standard external motor outline drawing:

![]()

Notes:

Lead screw length can be customized

Customized machining is viable at the end of lead screw

Please contact us for more ball screw specifications.

VSM20BSHSMBall nut 0601 outline drawing:

![]()

Speed and thrust curve:

20 series 30mm motor length bipolar Chopper drive

100% current pulse frequency and thrust curve

![]()

20 series 42mm motor length bipolar Chopper drive

100% current pulse frequency and thrust curve

![]()

| Lead (mm) | Linear velocity (mm/s) | ||||||||

| 1 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

Test condition:Chopper drive, no ramping, half micro-stepping, drive voltage 24V

Areas of application:

Laboratory Automation: 20mm hybrid ball screw stepper motors find applications in laboratory automation systems, including liquid handling robots, sample handling systems, and lab equipment. They enable precise and accurate positioning of instruments and samples, contributing to efficient and reliable laboratory workflows.

Industrial Automation: These stepper motors are used in various industrial automation applications such as pick-and-place machines, assembly systems, and conveyor systems. They provide precise control of motion and positioning, ensuring efficient and reliable operation in manufacturing and production environments.

Analytical Instruments: 20mm hybrid ball screw stepper motors are utilized in analytical instruments such as spectrometers, chromatography systems, and laboratory testing equipment. They enable precise movement and positioning of optical components, sample stages, and measurement devices, ensuring accurate and repeatable results.

Semiconductor Equipment: In the semiconductor industry, 20mm hybrid ball screw stepper motors are employed in equipment for wafer handling, alignment, and inspection. They play a crucial role in maintaining precise positioning and movement during the fabrication and testing processes.

Biotechnology and Life Sciences: These motors are used in biotechnology and life sciences applications, including DNA sequencing instruments, automated liquid handling systems, and cell manipulation devices. They provide the necessary precision and control for various laboratory processes and experiments.

Precision Machinery: 20mm hybrid ball screw stepper motors are commonly found in precision machinery such as precision stages, optical positioning systems, and metrology equipment. Their high positioning accuracy, repeatability, and smooth motion make them suitable for demanding applications that require sub-micron or nanometer-level precision.

Robotics and Motion Control: These stepper motors are employed in small robotic systems, robotic arms, and motion control systems that require accurate and controlled movements. They provide reliable and precise positioning, making them suitable for applications in research, education, and small-scale automation.

Advantage:

HIGH POSITIONING ACCURACY: The hybrid ballscrew structure allows the 20mm hybrid ballscrew stepper motor to achieve high accuracy positioning and motion control. The ball screw mechanism reduces the rotary clearance of the mechanical transmission, improving positioning accuracy and repeatability.

HIGH LOAD CAPACITY: The ball screw mechanism is capable of handling large loads, making the 20mm Hybrid Ball Screw Stepper Motor suitable for applications where heavier loads need to be carried.

HIGH RIGIDITY AND STABILITY: Ball screws are more rigid than traditional screw construction, providing more stable and reliable motion control. This helps to reduce vibration and slewing errors, improving system stability and accuracy.

High Efficiency: Due to the highly efficient drive characteristics of the ballscrew, the 20mm Hybrid Ball Screw Stepper Motor has a high transmission efficiency, reducing energy loss and heat generation.

High-speed motion: Hybrid ball screw stepper motors combine the advantages of stepper motors with the transmission characteristics of ball screws, thus enabling high motion speeds for applications requiring fast response and high-speed motion.

High Repeat Positioning Accuracy: The ball screw construction provides high repeat positioning accuracy, allowing the 20mm hybrid ball screw stepper motor to achieve precise repeat positioning for applications requiring high accuracy.

Static Holding Torque: The 20 mm Hybrid Ball Screw Stepper Motor maintains position even in the event of a power failure or cessation of current supply, without the need for an additional braking device.

Simplified control system: 20 mm hybrid ball screw stepper motors typically operate under an open-loop control system, eliminating the need for additional position feedback devices and simplifying control system design and installation.

Motor Selection Requirements:

►Movement/mounting direction

►Load Requirements

►Stroke Requirements

►End machining requirements

►Precision Requirements

►Encoder Feedback Requirements

►Manual Adjustment Requirements

►Environmental Requirements

Production workshop:

![]()

![]()