-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

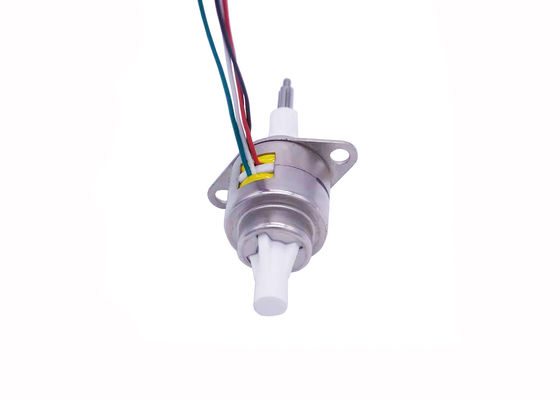

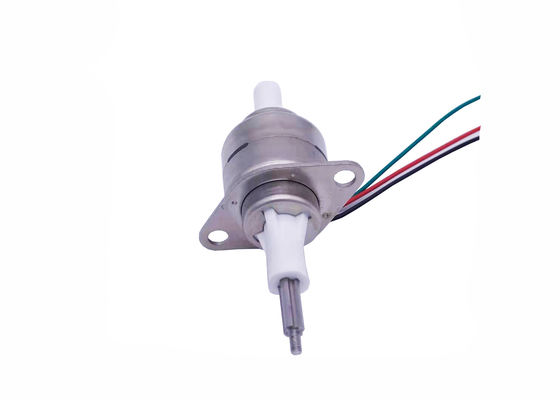

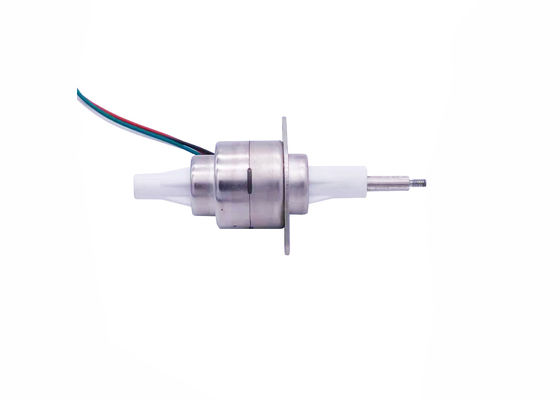

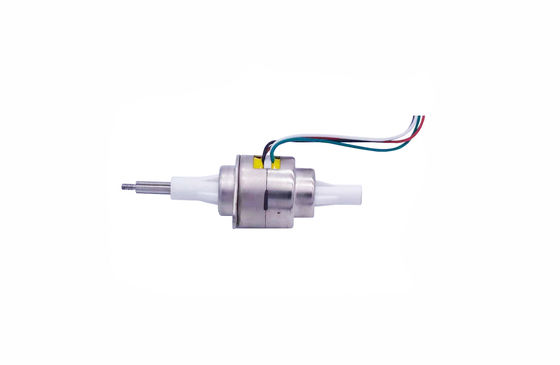

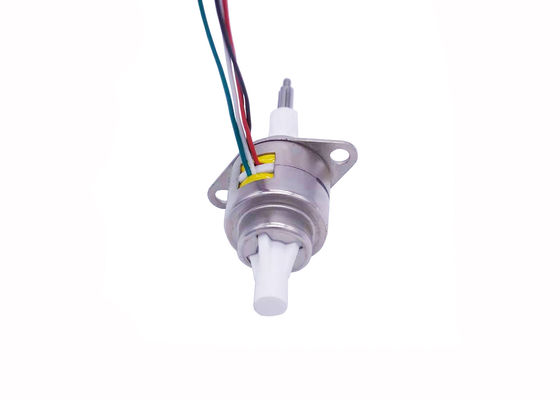

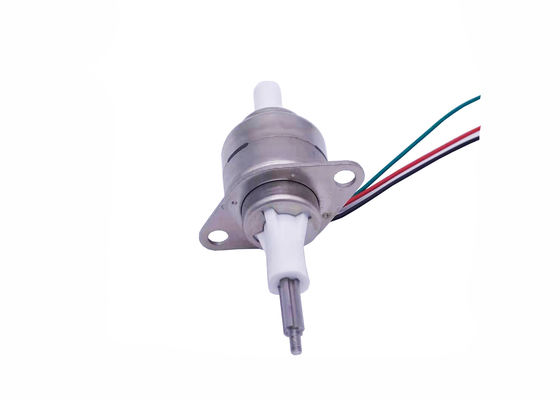

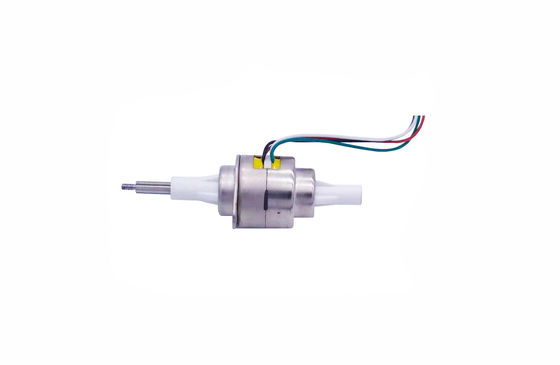

High Thrust 18mm Stroke Linear stepper Motor 7.5 Degree Step Angle 20mm Diameter for Medical Equipment

| Place of Origin | China |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS, ISO9001 |

| Model Number | VSM20L-48S-0127-18-01 |

| Minimum Order Quantity | 1Unit |

| Price | $6.5~$30/Unit |

| Packaging Details | Standard export package in corrugated carton (Mass production). |

| Delivery Time | 15-30 work days |

| Payment Terms | Western Union, T/T, L/C, MoneyGram |

| Supply Ability | 100000 Units/year |

| Motor Diameter | 20mm | Rated Voltage | 5V |

|---|---|---|---|

| Power | 3.4W | Phase Current | 385mA |

| Phase Inductance | 13(±10%)Ohm/20C | Phase Inductance | 6.5(±20%)Mh/1kmz |

| Step Angle | 7.5° | Screw Lead | 0.6096mm |

| Step Travel | 0.0127mm | Screw Length | 20mΩ(DC 500V) |

| Insulation Class | B | Mass | 35g |

| Highlight | 18mm Stroke Linear Dc Motor,7.5 Degree Linear Dc Motor,High Thrust 20mm Stepper Motor |

||

High thrust and high precision 18mm stroke 7.5° step angle 20mm diameter stepper motor

This stepper motor with a stroke diameter of 20mm has 48S steps per circle, and the motor's movement is completely controlled by the driver. This product can be used with precision instruments or electronic products, and is widely used in various fields of industry.

Our products can be customized, if you are interested, you can write to me.

![]()

Typical applications:

* Medical Equipment

* Linear Robotic Control

* Precision Calibration

* High Precision Valve

* Other Precise Position Movement

Design Layout (Unit:mm)

![]()

Parameter sheet:

|

Model No. |

VSM20L-48S-0127-18-01 |

|

Motor diameter |

20mm |

|

Rated voltage |

5V |

|

Power |

3.4W |

|

Phase Current |

385mA |

|

Phase Inductance |

13(±10%)Ohm/20C |

|

Phase inductance |

6.5(±20%)Mh/1kmz |

|

Step angle |

7.5° |

|

Screw Lead |

0.6096mm |

|

Step Travel |

0.0127mm |

|

Screw Length |

20mΩ(DC 500V) |

|

Insulation Class |

B |

|

Operating Temp Range |

-20~+55℃ |

|

Storang Temp Range |

-40~+100℃ |

|

Mass |

35g |

Competitive Advantage

-

High quality and the best price.

-

Fast deliver,storage company and rich inventory

-

Near Shanghai port, the traffic is very convenient.

Frequently Asked Question

1.How to reduce the heat of the stepper motor:

Reduce heat generation is to reduce copper loss and iron loss. Reduce copper loss in two directions, reduce resistance and current, which requires the selection of small resistance and rated current as small as possible when the motor, the two-phase motor, can use the motor in series without parallel motor. But this often contradicts the requirements of torque and high speed. For the selected motor, the drive's automatic half-current control function and offline function should be fully utilized, the former automatically reduces the current when the motor is at rest, and the latter simply cuts off the current. In addition, the subdivision drive, because the current waveform is close to sinusoidal, less harmonics, motor heating will also be less. There are few ways to reduce iron loss, and the voltage level is related to it. Although a motor driven by high voltage will bring an increase in high-speed characteristics, it also brings an increase in heat generation. So we should choose the right drive voltage level, taking into account the high speed, smoothness and heat, noise and other indicators.

2.Principle of stepper motor:

The speed of a stepper motor is controlled with a driver, and the signal generator in the controller generates a pulse signal. By controlling the frequency of the pulse signal sent, when the motor receives a pulse signal will move one step (we only consider the whole step drive), you can control the speed of the motor.

3.What factors affect the speed of a stepper motor?

The speed of a stepper motor is determined by the driver frequency, the step angle of the stepper motor and the gearbox.

Product Detail Presentation

![]()