-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

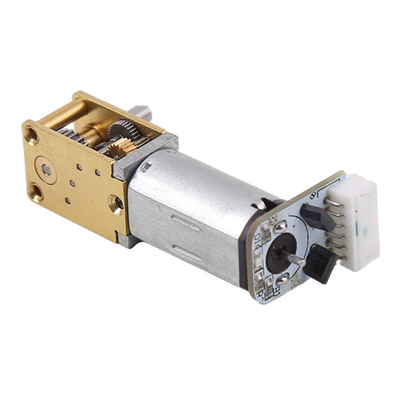

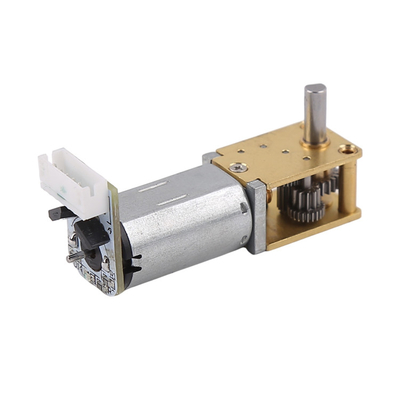

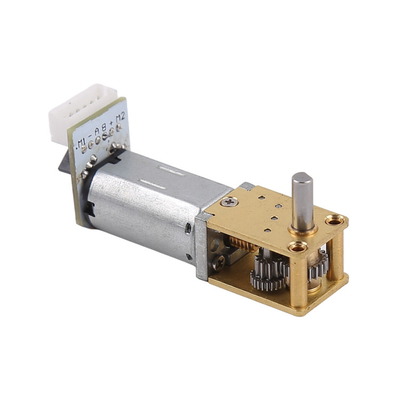

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

2.4~6V Load Speed 12250 RPM Brush DC Gear Motor With Worm Gear Box $3~$8.5/unit

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS |

| Model Number | N20*10*12*18 gear motor |

| Minimum Order Quantity | 1 Unit |

| Price | $3~$8.5/unit |

| Packaging Details | Standard export package, or can be customized |

| Delivery Time | 15-30 work days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 1000000Units per year |

| Voltage | 2.4~6( V ) | Output Power | 0.1~1.6( W ) |

|---|---|---|---|

| Type | DC Motor | Certification | CE, ROHS |

| Commutation | Brush | Gear Ratio | 1:118 1:236 1:603 |

| Encoder | Magnetic Encoder | ||

| Highlight | 12250 RPM Brush DC Gear Motor,6V Brush DC Gear Motor |

||

N20 brush DC motor attached with worm gear box and magnet encoder

![]()

Mechanical Dimension:MM

![]()

About DC brushed motors

DC brushed motor is the most commonly used motor in the market.

The DC motor has brushes inside, l positive and negative pins (+ and -).

The speed of a DC motor can be controlled with different gear ratios or with PWM (Pulse Width Modulation)

With the torque boost of the gearbox, the DC motor can reach higher torque compared to the original torque of the motor.

Typical Applications

- Office Automatic Equipments

- Printer/paper Feeder

- Bank Equipments

- Safe Box

- Ad Equipment

- Household Appliances

- Electtric Door Locks

N20 is a DC gear motor made of precious metal brushed DC motor with precision metal reducer. The outer dimensions are oblate, outer diameter 12, flat 10, motor length 15mm, the length of the gearbox is

18MM, DC motor because of mature technology, low price, simple drive control and widely used in cameras, copiers, door locks, optical drives, precision instruments, cameras and other fields.

After supporting the gearbox, the torque is greatly increased, the speed is reduced, and it is easy to control.

For the gearbox, we have different gearbox for you to choose from, regular gearbox and worm gearbox. For regular geabox, output shaft and motor shaft are on the same direction. For worm gearbox, output shaft is vertical to motor shaft.

Our gearboxes are processed and assembled by imported machine tools to ensure that the accuracy of each gear is higher than other manufacturers in the same industry, so the gearbox is stable in transmission, low in noise, high in efficiency, reliable in structure, long in life and quality.

There is a encoder attached at the bottom of the motor. It is a magnetic encoder with hall component. A hall component can test the position of a magnet ring. Therefore, when a motor rotates a turn, there will be several signal pulses generated (Pulse number depends on magnet poles on magnet ring). In this case, the motor will provide feedback signal, and users can tell how many turns the motor rotates based on encoder signal.

Our team has more than 10 years of experience in micro-motor design, development and production, so we can achieve product development and auxiliary design according to the special needs of customers!

Customer needs are our efforts, please feel free to contact us.

| Motor model | N20 DC motor |

| Gear ratio | 118:1, 236:1, 603:1 |

| Encoder resolution | 3, 6, 12 PPR(pulse per revolution) |

| Operating voltage | 1.5 ~ 6 V |

| No load speed | 15800 RPM |

| Load speed | 12250 RPM |

| Load torque | 2.91 g*cm |

| Stall torque | 13 g*cm |

advantages

Cost-Effective: The micro DC gear motor is generally less expensive than other types of motors, such as stepper motors. This makes it an attractive option for cost-sensitive applications.

Small Size: The micro DC gear motor is one of the smallest motors available, making it ideal for applications where space is limited. Its small size also makes it lightweight and easy to integrate into small devices.

Direct Connection: The micro DC gear motor can be directly connected to the load, making it easy to use. There is no need for complex control circuits or feedback systems.

Wide Range of Applications: The micro DC gear motor is used in a wide range of applications, including robotics, medical devices, consumer electronics, and industrial automation.

Fast Rotational Speed: The micro DC gear motor can achieve high rotational speeds, making it ideal for applications that require fast and precise movement.

Higher Efficiency: The micro DC gear motor is generally more efficient than stepper motors, which can result in lower power consumption and longer battery life.

High Torque: The micro DC gear motor can provide high torque, making it ideal for applications that require high force or torque output.

Reliable: The micro DC gear motor is highly reliable, with a long lifespan and low failure rate. It is also resistant to shock and vibration, making it ideal for use in harsh environments.

the micro DC gear motor offers numerous advantages over other types of motors. Its cost-effectiveness, small size, direct connection, wide range of applications, fast rotational speed, higher efficiency, high torque, and reliability make it an ideal choice for many applications.

Product Detail Presentation

![]()

![]()

![]()

Lead Time and Packaging Information:

Lead time for samples:

Standard motors in stock: within 3 days

Standard motors not in stock: within 15 days

Customized products: About 25~30 days (based on complexity of customization)

Lead time for building a new mold: generally about 45 days

Lead time for mass production: based on order quantity

Packaging:

Samples are packed in foam sponge with a paper box, shipped by express

Mass production, motors are packed in corrugated cartons with transparent film outside. (shipping by air)

If shipped by sea, product will be packed on pallets