-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

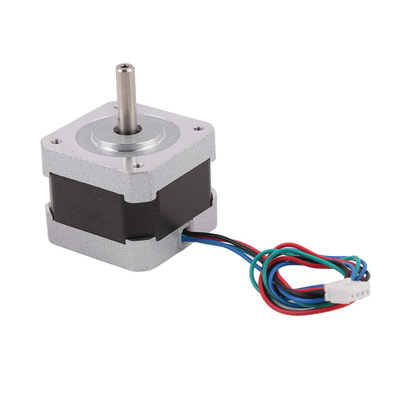

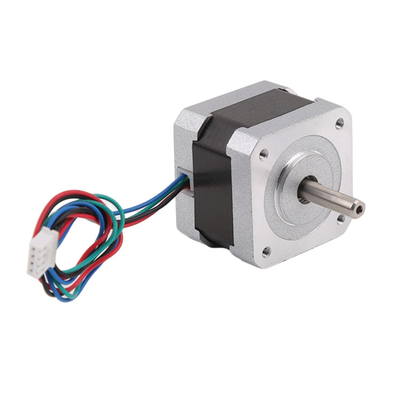

1.8° NEMA17 Hybrid Stepper Motor 42mm Length High Precision With D Shaft 3D Printer

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS |

| Model Number | VT42HS40 |

| Minimum Order Quantity | 1 Unit |

| Price | $4.5 - $10.00 / Units |

| Packaging Details | Standard export package, or can be customized |

| Delivery Time | 15-30 work days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 100000Units per month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Step Angle(degrees) | 1.8° | Voltage | 12 V |

|---|---|---|---|

| Current | 0.4 A | Type | Hybrid |

| Weight | 150 ~ 550 G |

1.8° NEMA17 Hybrid Stepper Motor 42mm Length High Precision With D Shaft 3D Printer

This is 42mm NEMA 17 hybrid stepper motor with 5mm diameter D shaft.

This motor is used for precise control.

Step angle is 1.8 degrees, there are different motor length and torque for you to choose.

The longer the motor’s height, it has bigger torque.

Mechanical Dimension:MM

![]()

Typical Applications

The NEMA 17 hybrid stepper motor is a high performance, high precision motor with many advantages. It can be used in a wide range of applications in many different fields. The following are some of the main applications for NEMA17 hybrid stepper motors:

3D printers: NEMA17 hybrid stepper motors are often used in 3D printers to control the movement of the print head and ensure accurate print results.

Surveillance equipment: NEMA17 hybrid stepper motors are also commonly used in surveillance equipment, such as rotating or moving cameras and autofocus mechanisms, to ensure accurate surveillance results.

Medical machinery: NEMA17 hybrid stepper motors are also frequently used in medical equipment, such as infusion pumps and surgical robots, to ensure precision and accuracy in the movement and positioning of machines.

Vending machines: NEMA17 hybrid stepper motors are often used in vending machines, for example, to control the opening and closing of aisles and the placement of goods to ensure the efficient operation of the vending machine.

Construction vehicles: NEMA17 hybrid stepper motors are also commonly used in construction vehicles, for example to control the movement of robotic arms and hydraulic pumps to ensure accurate operation of the machine.

CNC engraving machines: NEMA17 hybrid stepper motors are also widely used in CNC engraving machines, for example, to control the movement and cutting of the cutter head to ensure high precision engraving results.

ATM machines: NEMA17 hybrid stepper motors are also often used in ATM machines, for example, to control the opening and closing of bill exits and withdrawal slots to ensure efficient ATM machine operation.

In addition to the above applications, NEMA17 hybrid stepper motors are also widely used in robotics, automation equipment, textile machinery, printing machinery, and winding machines. In short, the NEMA17 hybrid stepper motor is a high-performance, high-precision, multifunctional motor that can meet the needs of many different applications.

Technique Parameter

| Model No. | VT42HS40 |

| Motor type | Hybird stepper motor |

| Motor size | 42*42mm (NEMA17) |

| Motor height | 28mm/34mm/40mm/48mm/60mm |

| Output shaft | 5mm D shaft |

| Shaft length | 24mm |

| Weight | 150 ~ 550 grams |

advantages:

Low Heat Generation: NEMA17 hybrid stepper motors generate less heat during operation, which is beneficial for applications where heat dissipation is a concern. This is because they operate at a lower current than other types of motors, which reduces the amount of heat generated.

High Efficiency: NEMA17 hybrid stepper motors are highly efficient, which means they can convert a large amount of electrical energy into mechanical energy. This makes them ideal for applications where energy efficiency is critical, such as battery-powered devices and solar-powered systems.

Easy to Control Speed and Direction: NEMA17 hybrid stepper motors are easy to control when it comes to speed and direction. This is because they respond quickly to changes in the input signal, and the number of steps per revolution can be easily adjusted.

Low Maintenance: NEMA17 hybrid stepper motors require very little maintenance, which is another advantage for many applications. They do not have brushes or commutators, which are parts that require frequent replacement in other types of motors.

Flexibility: NEMA17 hybrid stepper motors offer a high degree of flexibility in terms of customization. They can be customized for specific applications, including different shaft sizes, mounting configurations, and electrical specifications.

Cost-Effective: NEMA17 hybrid stepper motors are cost-effective compared to other types of motors that offer similar performance. This is because they are mass-produced and widely available, which reduces the cost of production.

High Torque-to-Size Ratio: NEMA17 hybrid stepper motors have a high torque-to-size ratio, which means they can deliver a large amount of torque in a small package. This is beneficial for applications where space is limited, such as in portable medical equipment and drones.

Overall, NEMA17 hybrid stepper motors offer a wide range of advantages that make them suitable for many different applications. These advantages include high precision, high torque, smooth operation, energy efficiency, ease of control, low maintenance, flexibility, cost-effectiveness, and a high torque-to-size ratio.

Torque Curve For ReferenceThe above products are only representative models, we can customize the products according to customer requirements. Includes the length and diameter of the shaft.Our company can also provide OEM services.

Product Detail Presentation

![]()

Packaging and Shipping information:

Samples are packed with foam sponge inside paper box.

For mass production, products are packed in paper carton.

For sea shipping (Mass production), cartons are packed on pallet.

Shipping time:

By express(DHL/ UPS/ Fedex/ TNT): 5~12 days

By 4PX express: 10~20 days

Sea shipping: 40~60 days (depends on different countries)

![]()