-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

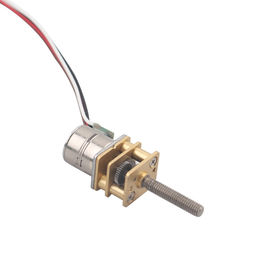

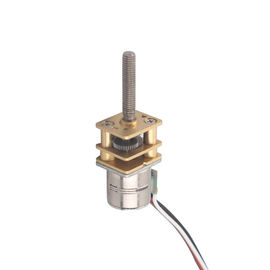

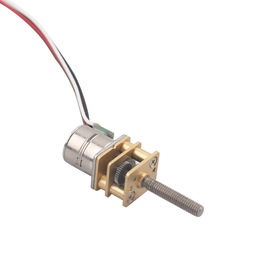

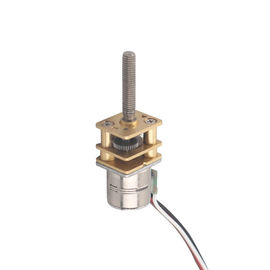

5VDC 10mm customizable1:3~1000 Mini Stepper Motor , 2 phase 4 wire High Torque Stepper Motor for Welding Machine,etc

| Place of Origin | China |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS |

| Model Number | SM10-816G |

| Minimum Order Quantity | 1Unit |

| Price | $5~7/unit |

| Packaging Details | Standard export package, or can be customized |

| Delivery Time | 10~30 days after the sample is paid |

| Payment Terms | MoneyGram, Western Union,Credit Card,T/T, L/C |

| Supply Ability | 10000 PCS 45days |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Type | Gear Motor | Construction | Permanent Magnet |

|---|---|---|---|

| Certification | ROHS | Voltage(v) | 5V |

| Output Shaft | D Axis Or Lead Screw Axis Customizable | Reduction Ratio | Customizable1:3~1000 |

| Directions | CW/CCW | Step Angle | 18 Degree |

| Current / Phase | 0.25A | Resistance | 20Ω~40Ω |

| Highlight | micro linear stepper motor,electric linear actuator motor |

||

5V 10mm mini screw stepper motor High torque linear stepper motor

The SM10-816G adopts a combination of a 10MM diameter micro stepper motor and a 10 * 12 precision metal gearbox. The motor diameter is 10mm, and the gear reduction ratio is 1:2 1:5 1:10 1:15 1:20 1:30 1:36 1:50 1:63 1:67 1:89 1:100 1:110 1:150 1:150 1:172 1:210 1:250 1:275 1:298 1:380 1:420 1:500 1:600 1:1000. The reduction ratio can be customized according to customer needs.

The basic step angle of the motor is 18 degrees, which is 20 steps per revolution. Combined with the deceleration effect of the gearbox, the final motor rotation angle resolution can reach 0.05-6 degrees, which can be used for various requirements.

Accurately control the rotational position of the magnetic field.

For the output of the motor, it is usually a connecting wire, and FPC or bare needle can be customized according to customer installation needs. The output shaft of the motor's conventional gearbox is M3 screw or D-axis, and the output shaft can also be customized according to customer installation needs

![]()

Mechanical Dimension:MM

![]()

Technical Features

Given the proper driving frequency of the stepper motor can reach the determination of the speed and torque.

This product gear box uses the most advanced equipment in the international processing related parts, so the high precision, high efficiency, low noise, and the use of reasonable and reliable process, make the product has better reliability.

The power input part and standard stepper motor can be used as probe structure, FPC, FFC, PCB cable and other forms.

Part of the output of the motor can be used in a variety of output structure, such as the circular axis, D axis, and the wire rod!

Typical Applications

- Saliva Analyzer

- Blood Analyzer

- Welding Machine

- Intelligent Security Products

- Fiber Fusion Splicer

- Digital Electronics

Specifications

| PRODUCT NAME | 10mm geared stepper motor |

| MODEL | VSM10-816G |

| RESISTENCE | 40Ω±7% |

| OPERATING TEMPERATURE RANGE | -0~+55 ℃ |

| OEM & ODM SERVICE |

AVAILABLE |

Product Detail Presentation

![]()

![]()