-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

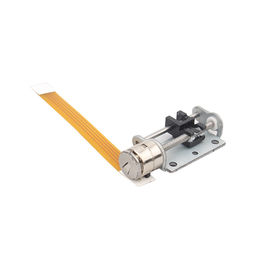

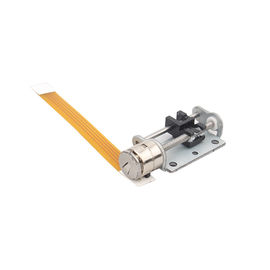

Durable 8mm 2 Phase 18 degree Weight 5.5 g PM Stepper Motor For Precision Medical Devices

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS |

| Model Number | VSM0806 |

| Minimum Order Quantity | 1 Unit |

| Price | $2.8~$7/Unit |

| Packaging Details | Selling Units: Single item plastic box inner , outer paper box Package: single carton packing, 100 - 1000 pieces per box. Lead Time : 30 Days After Deposit |

| Delivery Time | 15-30 work days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 1000000 Units/year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Step Angle(degrees) | 18 Degree | Phase | 2 |

|---|---|---|---|

| Voltage | 3.3 V | Resistance | 20 Ω±10% |

| Weight | 5.5 G | Rotation | CW/CCW |

| Type | Permanent Magnet | Holding Torque | 1.5gf.cm~2.0gf.cm |

| Highlight | mini slider screw stepper motor,lead screw motor |

||

VSM0806 8mm slider stepper motor 2 phase pm stepper motor for precision medical devices

The stepping motor has a step angle of 18 degrees. In the case of full step (2-2 phase excitation) driving, the motor rotates 20 steps per revolution, and the commonly used pitch of the screw is 0.4 mm, so the position control accuracy can reach 0.02 mm. If you need to further improve the accuracy, you can customize to reduce the screw pitch and other methods. It can also be realized with a higher precision motor (stepping motor with a step angle of 9 degrees).

In general, the stepping motor has a thrust of about 150 to 300 g, which varies depending on the driving voltage, the motor resistance, and the like.

![]()

Mechanical Dimension:MM

![]()

VSM0806 slider stepper motor for monitoring devices.Miniature stepper motor is equipped with a special bracket, screw and slider (linear motion module)Because the stepping motor is small in size, high in precision, easy to install, easy to use and many other advantages, it is widely used in various industries such as monitoring devices, projectors, medical instruments, optical lenses, small instruments, smart meters, automatic door locks.

The main function of micro stepper motor is to move specific parts (such as lenses, measuring strips, locking tongues, probes) to the exact position according to the instructions of the host computer, control computer or other control devices, so as to achieve the corresponding Focus, test and other functions.

The input part of the stepping motor power supply can be in various forms such as an FPC connector, a connection wire connector, and a light pin (for direct soldering of the PCB). The push rod of the output part can be either a plastic slider or a metal slider, which can be customized according to customer requirements. The stroke of the slider can be customized according to the customer's requirements within a certain range, but because the motor is small, the screw is thin (currently used M2), the length of the thread that can be processed is limited, and the maximum stroke is generally less than 50mm. Stroke 40mm.

Our team has more than 10 years of experience in the design, development and production of micro stepping motors. We can implement product development and auxiliary design of client products according to the special needs of customers!

The drive control system for the motor is also our specialty and can be customized for the customer.

Customer needs are our efforts, please feel free to contact us!

Typical Applications

-

Intelligent Security Products

-

Camera Lenses

-

Door Locks

-

Wearable device

Specifications

| Product Name | 8mm slider stepper motor | |||

| Model | VSM0806 | |||

| Rated Voltage | 3.3V | |||

| Current Per Phase | 150 mA /phase | |||

| Coil Resistance | 20 Ω±7% | |||

| No. Of phase | 2 Phases | |||

| Step Angle | 18 degree | |||

| Excitation Method | 2 Phase Excitation | |||

| Drive Mode | Bipolar Drive | |||

| Pull-In Torque | 1.5 gf.cm At 500 pps | |||

| Pull-Out Torque | 2.0 gf.cm At 500 pps | |||

| Max. Response Frequency | 800 pps, | |||

| Max. Starting Frequency | 2000 pps, | |||

| Insulation Class | Class E for Coils | |||

| Insulation Strength | 100 V AC for One Second | |||

| Insulation Resistance | 1.0 MΩ (DC 100 V) | |||

| Operating Temperature Range | -10~+60 ℃ | |||

| Weight | 5.5 g(Ref.) | |||

| OEM & ODM SERVICE | AVAILABLE | |||

Competitive Advantage

- High quality and the best price.

- Fast deliver,storage company and rich inventory

- Near Shanghai port, the traffic is very convenient.

Customization service

Motor’s design can be adjusted based on customer’s requirement including:

Motor’s diameter: we have 6mm, 8mm, 10mm, 15mm and 20 mm diameter motor

Coil resistance/ rated voltage: coil resistance is adjustable, and with higher resistance, motor’s rated voltage is higher.

Bracket design/ lead screw length: if customer want the bracket to be longer/short, with special design such as mounting holes, it’s adjustable.

PCB + cables + connector: PCB’s design, cable length and connector pitch are all adjustable, they can be replaced into FPC if customers require.

Torque Curve For Reference

![]()

![]()

Type Of Wire Connect For Reference

The motor input part of the FPC, but can according to the customer demand can be changed to a connecting line needle, PCB and other forms.

The mounting bracket can be changed according to the customer's request.

![]()

Product Detail Presentation

![]()

![]()

![]()