-

Micro Stepper Motor

-

Permanent Magnet Stepper Motor

-

Geared Stepper Motor

-

Linear Stepper Motor

-

Slider Stepper Motor

-

Hybrid Stepper Motor

-

Small DC Gear Motor

-

ROV Thruster Motors

-

Micro Metal Gearmotor

-

Micro Gearbox

-

Position Control Stepper Motor

-

3D Printer Stepper Motor

-

Stepper Motor Driver

-

DC Motor Controller

-

Lead Screw And Nut

-

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good.

Andres BlancoThe thruster have arrived correctly. I tested them on the ROV and we are very happy with the result. The epoxy interior finish is very good and the power of the motors in relation to the size is quite good. -

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend !

Gregoire LangeThe cooperation between Changzhou Vic-Tech Motor Tech and our company was just great. Good understanding of our needs, great willing to solve our problems. I recommend ! -

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed !

David MoleveltProfessional and clear communication. Order was shipped in time. Counter connectors where added to the shipment. Driver works like we agreed ! -

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you.

Buildstorm Private LimitedThe product works as expected, it was packed nicely. Seller responds very quickly and helps in making a buying decision. They are ready to customize the product for you. -

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

Ashley GriffinShipment was received very quickly. Product was well protected by packaging. Company rep was cordial and kind. A Plus rating!

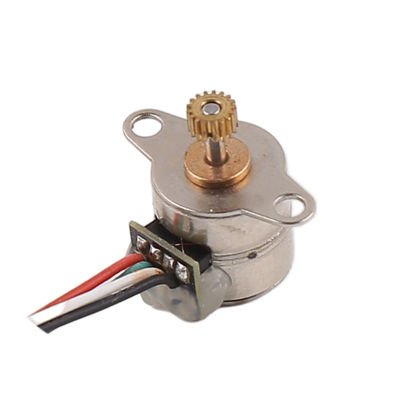

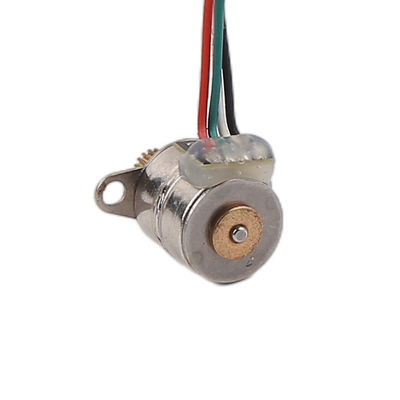

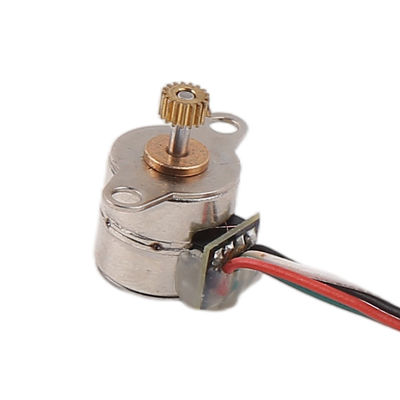

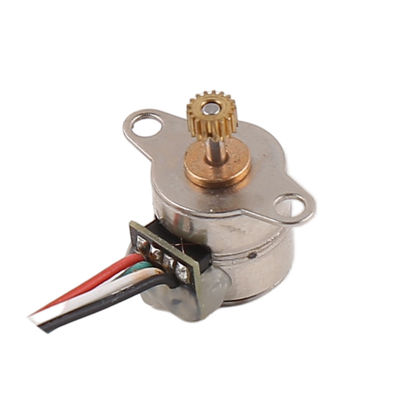

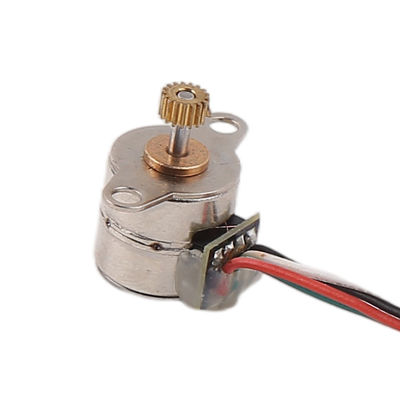

5V 2 Phase PM Stepper Motor

| Place of Origin | Jiangsu, China (Mainland) |

|---|---|

| Brand Name | VIC-TECH |

| Certification | RoHS |

| Model Number | VSM1070 |

| Minimum Order Quantity | 1Unit |

| Price | $2~$5/Unit |

| Packaging Details | Selling Units: Single item plastic box inner , outer paper box Package: single carton packing, 100 - 1000 pieces per box. Lead Time : 30 Days After Deposit |

| Delivery Time | 15-30 work days |

| Payment Terms | T/T, Western Union, MoneyGram |

| Supply Ability | 1000000 Units/year |

| Step Angle(degrees) | 18 | Phase | 2 |

|---|---|---|---|

| Voltage | 5V | Current / Phase | 250mA/Phase |

| Resistance | 20Ω±7% | Weight | 5.5g |

| Rotation | CW/CCW | Type | Permanent Magnet |

| Highlight | Intelligent Security Micro Stepper Motor |

||

VSM1070 micro stepper motor 5V 2 phase pm stepper motor for intelligent security

Motor basic step angle is 18 degrees, that is, 20 steps per turn, plus the deceleration box deceleration effect, the final motor rotation angle resolution can reach 0.05~6 degrees, can be used in many requirements

![]()

Mechanical Dimension:MM

![]()

About Micro stepper motor:

Our micro stepper motors generally have 18 degrees step angle.(Full step driving)

That means it takes 20 steps to rotate one turn.

Motor’s step angle is related to internal stator’s design.

We have micro stepper motors with different diameters, and motor’s torque is related to its size.

Here is relationship between motor’s diameter and torque(with suitable running frequency, at rated voltage):

6mm motor: about 1 g*cm

8mm motor: about 3g*cm

10mm motor: about 5 g*cm

15mm motor: about 15 g*cm

20mm motor: about 40 g*cm

Typical Applications

The 10mm micro stepper motor is a popular choice for a wide range of applications due to its small size, precision, and reliability. Here are some of the areas where this type of motor is commonly used:

Smart Security Products: The 10mm micro stepper motor is used in various smart security products such as access control systems, smart door locks, and surveillance cameras. These products require precise and reliable motors to ensure smooth and accurate movement.

Camera Lenses: The 10mm micro stepper motor is also used in camera lenses, including digital cameras, DSLRs, and action cameras. They are used to control the focus and zoom functions of the lenses.

Wearable Devices: The 10mm micro stepper motor is a popular choice for wearable devices such as smartwatches, fitness trackers, and other portable devices. These devices require small, lightweight, and energy-efficient motors.

Medical Devices: The 10mm micro stepper motor is used in various medical devices such as pumps, dispensers, and analyzers. These devices require precise and reliable motors to ensure accurate dosing and analysis.

Robotics: The 10mm micro stepper motor is used in various types of robots, including industrial robots, robotic arms, and humanoid robots. These robots require precise and reliable motors for smooth and accurate movement.

Consumer Electronics: The 10mm micro stepper motor is used in various consumer electronics products such as smartphones, tablets, and laptops. They are used for various functions such as haptic feedback, vibration, and camera control.

Automotive Applications: The 10mm micro stepper motor is used in various automotive applications such as electric power steering, throttle control, and HVAC controls. These applications require precise and reliable motors to ensure smooth and accurate operation.

Industrial Automation: The 10mm micro stepper motor is used in various industrial automation applications such as CNC machines, 3D printers, and textile machines. These applications require precise and reliable motors for precise and repeatable movement.

the 10mm micro stepper motor is a versatile motor that finds applications in a wide range of products and industries. Its small size, precision, and reliability make it an ideal choice for many applications.

Specifications

| Product Name | 10mm micro stepper motor | |||

| Model | VSM1070 | |||

| Current Per Phase | 250mA /phase | |||

| Coil Resistance | 20Ω±7% | |||

| No. Of phase | 2 Phases | |||

| Step Angle | 18 degree | |||

| Excitation Method | 2 Phase Excitation | |||

| Drive Mode | Bipolar Drive | |||

| Pull-In Torque | More Than 5.0gf.cm At 500 pps | |||

| Pull-In Out | More Than 6.0gf.cm At 500 pps | |||

| Hoiding Torque | More Than 13.0gf.cm At 500 pps | |||

| Max. Response Frequency | More Than 1500 pps | |||

| Max. Starting Frequency | More Than 1000 pps | |||

| Insulation Class | Class E for Coils | |||

| Insulation Strength | 100V AC for One Second | |||

| Insulation Resistance | 50MΩ DC 500 V | |||

| Operating Temperature Range | -0~+55 ℃ | |||

|

Lead Wire |

UL1571 28# | |||

| Weight | 5.5g | |||

| OEM & ODM SERVICE | AVAILABLE | |||

Competitive Advantage

The 10mm micro stepper motor is a popular choice for many applications due to its numerous advantages over other types of motors. Here are some of the key advantages of the 10mm micro stepper motor:

Small Size: The 10mm micro stepper motor is one of the smallest motors available, making it ideal for applications where space is limited. Its small size also makes it lightweight and easy to integrate into small devices.

Low Power Consumption: The 10mm micro stepper motor is energy-efficient, consuming less power than other types of motors. This makes it an ideal choice for battery-powered devices, where energy efficiency is critical.

Precise Positioning: The 10mm micro stepper motor is capable of precise positioning, making it ideal for applications that require accurate and repeatable movement. Its ability to move in precise steps also makes it ideal for applications that require precise control over speed and torque.

Easy to Control: The 10mm micro stepper motor is easy to control, thanks to its simple design and precise stepping. It can be controlled using a simple driver circuit, without the need for complex feedback systems.

High Reliability: The 10mm micro stepper motor is highly reliable, with a long lifespan and low failure rate. It is also resistant to shock and vibration, making it ideal for use in harsh environments.

Low Noise: The 10mm micro stepper motor produces very little noise, making it ideal for applications where noise is a concern. This makes it an ideal choice for applications such as camera lenses and robotics.

Low Cost: The 10mm micro stepper motor is relatively inexpensive, making it an ideal choice for cost-sensitive applications. Its low cost also makes it an attractive option for mass-produced products.

Customizable: The 10mm micro stepper motor can be customized to meet specific application requirements, such as torque and speed. This makes it an ideal choice for applications that require customized motors.

the 10mm micro stepper motor offers numerous advantages over other types of motors. Its small size, low power consumption, precise positioning, ease of control, high reliability, low noise, low cost, and customizability make it an ideal choice for many applications.

Product Detail Presentation

![]()

![]()

![]()

Type Of Wire Connect For Reference

Motor input method with Pin type, FPC, PCB, Lead wire etc.

These can be customized according to customer needs.

![]()

Type of Fixture Cover

The regular models are shown in the figure, and the special sizes can be customized.

![]()

Lead Time and Packaging Information:

Lead time for samples:

Standard motors in stock: within 3 days

Standard motors not in stock: within 15 days

Customized products: About 25~30 days (based on complexity of customization)

Lead time for building a new mold: generally about 45 days

Lead time for mass production: based on order quantity

Packaging:

Samples are packed in foam sponge with a paper box, shipped by express

Mass production, motors are packed in corrugated cartons with transparent film outside. (shipping by air)

If shipped by sea, product will be packed on pallets